آخرین اخبار شرکت و صنعت را برای شما فراهم می کند

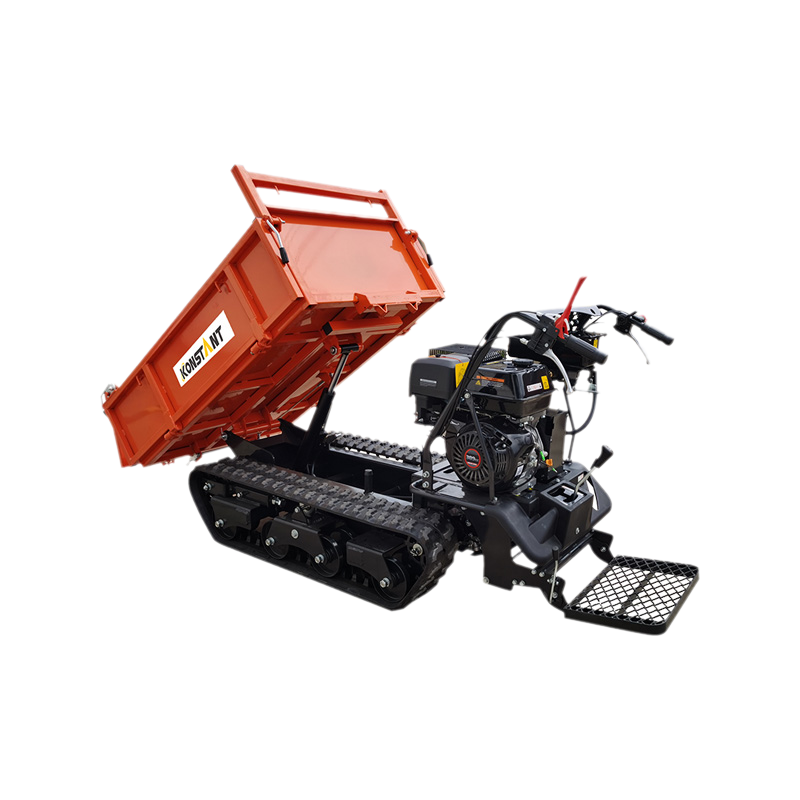

قدرت بارو چیست؟

Barrow Power یک وسیله نقلیه موتوری و چرخ دار است که برای کمک به حمل و نقل مواد و تجهیزات سنگین از طریق زمین های مختلف طراحی شده است. بر خلاف باروهای سنتی دستی یا چرخ دستی ، که کاملاً به تلاش انسان متکی هستند ، یک بارو برق از موتور یا موتور استفاده می کند تا بتواند قدرت لازم را برای جابجایی وسیله نقلیه و بار آن فراهم کند. این دستگاه ها معمولاً در ساخت و ساز ، محوطه سازی ، کشاورزی و سایر صنایع مورد استفاده قرار می گیرند که در آن به کار با مواد سنگین نیاز دارد.

بارو ابزاری اساسی برای بهبود بهره وری ، کاهش هزینه های نیروی کار و افزایش ایمنی در سایت های شغلی است. با کمک یک بارو برق ، کارگران می توانند مواد را به طور کارآمدتر حمل کنند ، که به ویژه در محیط هایی که زمان و فشار جسمی عوامل مهمی هستند ، از اهمیت ویژه ای برخوردار است.

عملکرد یک بارو برق

عملکرد اصلی یک بارو قدرت تسهیل حرکت مواد سنگین یا حجیم از یک مکان به مکان دیگر با حداقل تلاش انسان است. چه در حال حمل خاک ، شن ، آجر یا سایر مصالح ساختمانی باشد ، کمک موتوری بارو قدرت امکان حمل و نقل آسان از طریق زمین های مختلف از جمله زمین های خشن ، ناهموار یا تپه ای را فراهم می کند.

دست زدن به مواد: Barrow Power می تواند طیف وسیعی از مواد از جمله خاک ، ماسه ، سنگ ، ابزار و تجهیزات را حمل کند. این کمک می کند تا روند جابجایی این مواد در اماکن ساختمانی ، مزارع یا پروژه های محوطه سازی را ساده تر کند.

کاهش خستگی کارگر: با از بین بردن بار فیزیکی فشار دادن یک چرخ دستی سنتی ، یک بند قدرت خستگی را به حداقل می رساند و به کارگران این امکان را می دهد تا روی سایر کارها تمرکز کنند و برای دوره های طولانی تر و بدون فشار کار کنند.

قابلیت مانور پیشرفته: با داشتن چرخ های مجهز ، یک بارو قدرت می تواند به راحتی در محیط های کاری دشوار یا پر ازدحام حرکت کند که برای یک چرخ دستی دستی چالش برانگیز باشد. این می تواند از دامنه ها صعود کند ، از سطوح ناهموار عبور کند و از طریق فضاهای محکم فشرده شود و باعث بهبود کارایی مواد در محیط های پیچیده شود.

ویژگی های اساسی و عناصر طراحی یک بارو برق

یک بارو قدرت به طور معمول از چندین مؤلفه اصلی تشکیل شده است که آن را به ابزاری مؤثر و کارآمد برای حمل مواد تبدیل می کند:

منبع تغذیه موتوری: باروهای برق به طور معمول توسط موتور الکتریکی یا بنزینی تغذیه می شوند و نیروی لازم را برای انتقال بار فراهم می کنند. انتخاب نوع موتور به الزامات شغل و محیط بستگی دارد.

چرخ های بزرگ و بادوام : این دستگاه ها مجهز به چرخ های سنگین هستند که برای پایداری و کشش طراحی شده اند. چرخ ها اطمینان حاصل می کنند که Barrow Power می تواند ضمن حفظ بار پایدار ، سطوح خشن و ناهموار را تحمل کند.

کنترل های قابل تنظیم: کنترل های کاربر پسند ، که ممکن است شامل تنظیمات سرعت ، کنترل جهت و دریچه گاز باشد ، کار با استفاده از Barrow را آسان می کند. این کنترل ها به اپراتور اجازه می دهد تا حرکت و سرعت را بر اساس زمین و مواد حمل شده تنظیم کند.

ظرفیت بارگیری : Barrows Power برای حمل بارهای قابل توجهی طراحی شده است. بسته به این مدل ، آنها می توانند انواع مختلفی از مواد مختلف را از وسایل کوچک گرفته تا کالاهای سنگین تر و سنگین تر حمل کنند. قاب محکم برای پشتیبانی از بارهای با وزن بالا و بدون به خطر انداختن ثبات ساخته شده است.

دستگیره های ارگونومیک: دستگیره های Barrow برای راحتی و سهولت استفاده طراحی شده اند. آنها غالباً از نظر ارگونومیک برای کاهش فشار روی اپراتور ، به ویژه در هنگام استفاده گسترده طراحی شده اند.

چه چیزی باعث می شود یک بار قدرت از بارهای سنتی دست متفاوت باشد؟

Barrows Power مزایای قابل توجهی را نسبت به چرخ دستی های دستی سنتی ارائه می دهد ، عمدتا به دلیل عملکرد حرکتی و قابلیت های پیشرفته آنها. در اینجا تفکیک تفاوتهای کلیدی بین این دو آورده شده است:

تلاش دستی در مقابل قدرت موتوری: باروهای دست سنتی کاملاً به قدرت فیزیکی اپراتور برای جابجایی بار متکی است ، در حالی که باروهای برق از یک موتور یا موتور برای حمل بار استفاده می کنند و تلاش انسان را به طرز چشمگیری کاهش می دهد. این به معنای فشار کمتری به کارگر و زمان بیشتر برای کارهای دیگر است.

سرعت و کارآیی: باروهای برق بسیار سریعتر از چرخ دستی های دستی هستند ، به ویژه در محیط هایی که حجم زیادی از مواد باید به سرعت جابجا شوند. درایو موتوری به باروهای برق اجازه می دهد تا در زمان کمتری بارهای سنگین تری را در مسافت های طولانی تر حمل کنند.

سازگاری زمین: چرخ دستی های دستی محدود به سطوح نسبتاً صاف و مسطح است. در مقابل ، Barrows Power می تواند به زمین های خشن ، ناهموار یا شیب دار حرکت کند و آنها را برای مکان های ساختمانی ، مزارع و مناظر با شرایط زمین به چالش کشیده ایده آل کند.

ظرفیت حمل: باروهای دست سنتی در میزان وزنی که می توانند به دلیل محدودیت های فیزیکی کاربر داشته باشند محدود است. با این حال ، Barrows Power به لطف طراحی موتوری و ساخت و سازهای محکم ، به منظور حمل بارهای سنگین تر و بدون به خطر انداختن عملکرد طراحی شده است.

راحتی و ایمنی کاربر: Barrows Power فشار فیزیکی را در اپراتورها کاهش می دهد ، که برای کارگرانی که تمام روز وظایف کار با مواد را انجام می دهند ، از اهمیت ویژه ای برخوردار است. با به حداقل رساندن نیاز به فشار و بلند کردن دستی ، باروهای برق به کاهش خطر صدمات مانند سویه ها ، اسپرین ها و خستگی عضلات کمک می کند.

تطبیق پذیری در استفاده: در حالی که چرخ دستی های دستی برای بسیاری از کارهای نور به متوسط متنوع هستند ، باروهای برق برای کارهای سنگین و کاربردهایی که به عملکرد بالا نیاز دارند ، مناسب تر هستند ، مانند حمل مقادیر زیادی از بتن ، شن یا تجهیزات سنگین. آنها همچنین برای محیط های صنعتی که کارهای تکراری متداول است ، ایده آل هستند.

باروهای برق بنزین

باروهای قدرت بنزین متداول ترین نوع در صنایعی است که نیاز به قدرت و دوام بالا دارند. این مدل ها برای محیط های کاری در فضای باز ، به ویژه در اماکن بزرگ ساختمانی یا مزارع که دستگاه برای حرکت در زمین های خشن و ناهموار نیاز دارد ، ایده آل است.

برنامه: ایده آل برای ساخت و ساز ، محوطه سازی و عملیات کشاورزی که در آن به عملکرد سنگین مورد نیاز است. آنها اغلب برای حمل و نقل موادی مانند خاک ، ماسه ، ماسه و آوار در مسافت های طولانی یا در مناطق چالش برانگیز استفاده می شوند.

باروهای برق برقی

باروهای برق در مقایسه با همتایان بنزین خود ساکت تر و سازگار با محیط زیست هستند. این مدل ها برای استفاده در مناطقی طراحی شده اند که سطح سر و صدا نگرانی یا در محیط های داخلی باشد. باروهای برق معمولاً در فضاهایی مانند انبارها ، مهد کودک ها و عملیات در مقیاس کوچکتر که برق برای شارژ باتری در دسترس است ، استفاده می شود.

برنامه: ایده آل برای استفاده در سایت های ساختمانی شهری ، عملیات گلخانه ای و محیط های داخلی که در آن میزان انتشار سوخت ممنوع است. آنها برای حمل مواد سبک تر و در تنظیماتی که به ماشین آلات قدرتمند کمتری نیاز دارند استفاده می شود.

باروهای قدرت جمع و جور

Barrows Power Compact برای استفاده در فضاهای محدود یا برای کارهایی که نیاز به مانور در مناطق تنگ دارند ، طراحی شده اند. این مدل ها به طور معمول دارای قاب و چرخ های کوچکتر هستند اما ویژگی های موتوری باروهای قدرت استاندارد را حفظ می کنند.

کاربرد : در درجه اول در محوطه سازی مسکونی ، پروژه های ساختمانی در مقیاس کوچک یا تنظیمات داخلی که در آن فضا محدود است استفاده می شود. آنها برای حمل و نقل مواد در فضاهای کوچکتر مانند مسیرهای باغ ، درهای باریک یا بین ردیف های محصولات زراعی مناسب هستند.

باروهای قدرت سنگین

باروهای قدرت سنگین برای حمل بارهای بزرگتر و سنگین تر در مقایسه با مدل های استاندارد طراحی شده اند. این دستگاه ها مجهز به موتورهای قدرتمندتر و قاب های تقویت شده برای پشتیبانی از وزن قابل توجهی و بدون به خطر انداختن عملکرد هستند.

برنامه: مورد استفاده در پروژه های بزرگ ساختمانی ، معدن و سایر صنایع که نیاز به حمل و نقل مواد سنگین مانند سیمان ، سنگ های بزرگ یا آجر دارند. این باروهای قدرت برای کارهایی که حمل و نقل مواد فله ضروری است ایده آل است.

باروهای قدرت چند زمینی

این باروهای برق به طور خاص برای کار در زمین های چالش برانگیز مانند گل ، برف یا شیب های شیب دار طراحی شده اند. آنها مجهز به چرخ های پیشرفته یا آهنگ هایی هستند که کشش و پایداری بهتری را فراهم می کنند و به دستگاه اجازه می دهد تا سطوح متنوع و شرایط دشوار را کنترل کند.

کاربرد : در درجه اول در سایت های کشاورزی ، محوطه سازی یا ساختمانی با زمین خشن یا ناهموار مورد استفاده قرار می گیرد. آنها برای محیط هایی مانند مزارع ، پروژه های بزرگ در فضای باز و مناظر با شرایط خاک یا دامنه های چالش برانگیز مناسب هستند.

انواع قدرت بارو و کاربردهای آنها

| نوع بارو قدرت | شرح | کاربرد |

|---|---|---|

| باروهای برق بنزین | با استفاده از موتورهای بنزینی ، برای استفاده در فضای باز و ناهموار طراحی شده است. | ایده آل برای ساخت و ساز ، محوطه سازی و کارهای کشاورزی. برای حمل و نقل موادی مانند خاک ، شن و ماسه در زمین های چالش برانگیز استفاده می شود. |

| باروهای برق برقی | بر روی برق اجرا می شود و یک جایگزین ساکت تر و سازگار با محیط زیست برای مدلهای بنزین را فراهم می کند. | مناسب ترین برای سایت های ساخت و ساز شهری ، انبارها یا عملیات در مقیاس کوچکتر که در آن نیاز به تولید گازهای گلخانه ای به حداقل می رسد. |

| باروهای قدرت جمع و جور | اندازه کوچکتر برای استفاده در فضاهای محدود. | ایده آل برای محوطه سازی مسکونی ، پروژه های ساختمانی کوچک و فضاهای تنگ مانند مسیرهای باریک یا بین محصولات زراعی. |

| باروهای قدرت سنگین | طراحی شده برای حمل بارهای بزرگتر و سنگین تر با قاب های تقویت شده و موتورهای قدرتمندتر. | ایده آل برای پروژه های ساختمانی سنگین ، معدن و حمل و نقل مواد در محیط هایی با بارهای بزرگ و حجیم مانند آجر یا سیمان. |

| باروهای قدرت چند زمینی | مجهز به چرخ های مخصوص یا آهنگ برای کشش بهتر در زمین های ناهموار یا گل آلود. | در پروژه های کشاورزی و محوطه سازی با خاک یا دامنه های چالش برانگیز ، از جمله مزارع یا پروژه های فضای باز در زمین خشن استفاده می شود. |

مزایای استفاده از یک بارو برق

باروs چندین مزیت ارائه می دهد که آنها را به ابزاری ضروری برای صنایعی که نیاز به کارآیی مواد کارآمد دارند ، تبدیل می کند. این مزایا از افزایش بهره وری تا افزایش ایمنی برای کارگران متغیر است ، و آنها باعث می شوند که بارو یک سرمایه گذاری هوشمندانه برای مشاغلی که به دنبال بهینه سازی عملیات خود هستند.

افزایش کارایی و سرعت

Barrows برق به طور قابل توجهی زمان لازم برای جابجایی مواد سنگین را در مقایسه با چرخ دستی های دستی کاهش می دهد. با کمک موتوری خود ، آنها می توانند بارهای سنگین تری را در مسافت های طولانی تر در زمان کمتری حمل کنند و حمل و نقل مواد را بسیار سریعتر انجام دهند. این افزایش کارآیی منجر به زمان اتمام سریعتر پروژه و بهره وری کلی بالاتر می شود.

کاهش خستگی کارگر

یکی از مزایای اصلی باروهای قدرت ، کاهش فشار جسمی و خستگی برای کارگران است. بر خلاف چرخ های سنتی ، که برای فشار و بلند کردن نیاز به تلاش دستی دارند ، باروهای قدرت بخش اعظم بلند کردن سنگین را برای کاربر انجام می دهند. این امر خطر فشار عضلات ، خستگی و صدمات استرس تکراری را کاهش می دهد و باعث می شود محیط کار ایمن تر و راحت تر شود.

قابلیت مانور پیشرفته

Barrows Power به گونه ای طراحی شده است که حتی در شرایط چالش برانگیز به راحتی قابل مانور باشد. توانایی آنها در حرکت در زمین های خشن ، ناهموار یا شیب دار ، آنها را برای مکانهای ساختمانی ، مزارع و مناظر با شرایط پیچیده زمین ایده آل می کند. این توانایی برای عبور از زمین دشوار با اجازه دادن به اپراتورها برای حمل و نقل مواد در هر کجا که لازم باشد ، بدون در نظر گرفتن کیفیت سطح ، باعث افزایش بهره وری می شود.

افزایش ظرفیت بار

در مقایسه با چرخ دستی های دستی ، Barrows Power می تواند بارهای قابل توجهی سنگین تر داشته باشد و آنها را برای کارهایی که نیاز به حمل و نقل حجم زیادی از مواد دارند ، ایده آل می کند. ساخت و سازهای قوی و موتورهای قدرتمند آنها امکان حمل و نقل مواد فله ای مانند کیسه های بزرگ سیمان ، ماسه یا شن را فراهم می کند بدون اینکه عملکرد به خطر بیاندازد.

ایمنی بهبود یافته

کمک موتوری ارائه شده توسط Barrows Power ، احتمال بروز حوادث ناشی از خطای انسانی یا خستگی را کاهش می دهد. کارگران در هنگام بلند کردن بارهای سنگین ، کمتر خود را فشار می دهند و افزایش پایداری بارو قدرت باعث می شود که اپراتورها بتوانند مواد را از روی سطوح ناهموار حمل کنند. علاوه بر این ، Barrows Power اغلب مجهز به ویژگی های ایمنی مانند سیستم ترمز و کنترل پایداری برای جلوگیری از اوج یا از بین رفتن کنترل است.

مقرون به صرفه

در حالی که سرمایه گذاری اولیه در یک بارو قدرت ممکن است بالاتر از یک چرخ دستی دستی باشد ، مزایای بلند مدت از هزینه ها بیشتر است. Barrows Power با افزایش کارایی و به حداقل رساندن زمان صرف شده برای انجام وظایف ، هزینه های نیروی کار را کاهش می دهد. آنها همچنین با کاهش خطر آسیب و خستگی ، عمر کارگران را افزایش می دهند. با گذشت زمان ، پس انداز ناشی از کاهش هزینه های نیروی کار و بهبود بهره وری منجر به بازده مثبت سرمایه گذاری می شود.

تطبیق پذیری

Barrows Power فوق العاده همه کاره است و می تواند در طیف گسترده ای از برنامه ها مورد استفاده قرار گیرد. از ساخت و ساز و محوطه سازی گرفته تا کشاورزی و مدیریت رویداد ، این ماشین ها با وظایف و محیط های مختلف سازگار هستند. توانایی حمل و نقل انواع مواد - از جمله خاک ، آوار ، آجر و مالچ - باعث می شود که نیروگاه های قدرت مناسب برای صنایع و پروژه های متنوع باشد.

پایداری

به ویژه باروهای برق ، جایگزین سازگار با محیط زیست برای مدلهای بنزین ارائه می دهد. این دستگاه ها تولید گازهای گلخانه ای کمتری را تولید می کنند و کمتر در آلودگی هوا نقش دارند و آنها را برای مشاغل به دنبال کاهش ردپای کربن خود انتخاب خوبی می کند. از آنجا که صنایع بیشتر روی پایداری تمرکز می کنند ، برقی های برق گزینه ای برای استفاده از مواد ، گزینه سبزتر را ارائه می دهند.

مزایای استفاده از یک بارو برق

| سود | شرح |

|---|---|

| افزایش کارایی و سرعت | Barrows Power مواد سنگین را بسیار سریعتر از چرخ دستی های دستی حرکت می دهد و امکان تکمیل کار سریعتر و بهره وری بالاتر را فراهم می کند. |

| کاهش خستگی کارگر | با استفاده از کمک های موتوری ، باروهای برق ، فشار فیزیکی را برای کارگران کاهش می دهد ، از خستگی و خستگی جلوگیری می کند. |

| قابلیت مانور پیشرفته | این دستگاه ها به گونه ای طراحی شده اند که به طور کارآمد بر روی زمین های خشن و ناهموار حرکت کنند و آنها را برای شرایط مختلف کار مناسب می کنند. |

| افزایش ظرفیت بار | باروهای برق می توانند بارهای سنگین تر و حجیم تری را در مقایسه با چرخ های سنتی حمل کنند و سرعت حمل و نقل مواد را بهبود بخشند. |

| ایمنی بهبود یافته | با کاهش نیاز به بلند کردن دستی ، به حداقل رساندن خستگی و ارائه ثبات برای اپراتور ، خطر آسیب دیدگی را کاهش می دهد. |

| مقرون به صرفه | با وجود سرمایه گذاری اولیه ، Barrows Power با کاهش هزینه های نیروی کار و افزایش بهره وری ، پس انداز بلند مدت را ارائه می دهد. |

| تطبیق پذیری | مناسب برای طیف گسترده ای از مواد و محیط ، آنها را برای صنایع مختلف مانند ساخت و ساز و محوطه سازی مفید می کند. |

| پایداری | مدل های برقی با کاهش انتشار گازهای گلخانه ای و ارائه یک روش سبزتر برای حمل و نقل مواد ، گزینه سازگار با محیط زیست را فراهم می کنند. |

چه تفاوتی بین یک بارو برق و یک چرخ دستی برقی وجود دارد؟

هنگام بحث در مورد تجهیزات انتقال مواد ، از اصطلاحات برق و چرخ دستی برقی استفاده می شود. با این حال ، آنها دستگاه های مجزا با ویژگی های خاص هستند که آنها را از نظر عملکرد و طراحی از هم جدا می کنند.

1 منبع تغذیه

مهمترین تفاوت بین یک بارو برق و یک چرخ دستی برقی در منبع تغذیه آنها نهفته است.

قدرت بارو: یک بارو برق به طور معمول به یک وسیله نقلیه موتوری اشاره دارد که می تواند از موتور بنزینی یا موتور الکتریکی تغذیه شود. مدل های بنزین با استفاده از بنزین بیشتر در محیط های ناهموار و در فضای باز مانند اماکن ساختمانی ، که در آن به عملکرد سنگین مورد نیاز است ، استفاده می شود. باروهای برق با بنزین قدرت بیشتری را ارائه می دهند ، که به آنها امکان می دهد بارهای بزرگ و سنگین را در مسافت های طولانی یا زمین دشوار کنترل کنند.

چرخ دستی برقی: همانطور که از نام آن پیداست ، یک چرخ دستی برقی فقط با برق تغذیه می شود. این دستگاه برای عملیات ساکت تر ، تمیزتر و سازگار با محیط زیست ایده آل است. موتور الکتریکی آن را برای محیط های داخلی یا مناطقی که نیاز به انتشار گازهای گلخانه ای دارند مناسب می کند. در حالی که ممکن است همان قدرت خام یک موتور بنزینی نداشته باشد ، اما برای کارهای کوچکتر پایدارتر و مناسب تر است.

2. عملکرد و قدرت

Barrow Power: Barrows Power برای حمل بارهای سنگین تر ساخته شده و در محیط های خواستار تر فعالیت می کند. آنها غالباً دارای ظرفیت وزن بالاتری هستند و می توانند از زمین های خشن ، از جمله گل ، شن و شیب های شیب دار عبور کنند. موتورهای قدرتمند آنها آنها را برای پروژه های بزرگ ساختمانی ، کشاورزی و کاربردهای صنعتی ایده آل می کند.

چرخ دستی برقی: از طرف دیگر ، چرخ های برقی به طور معمول برای کارهای سبک تر و محیط های کاری مناسب تر هستند که در آن قدرت بالا به اندازه مهم نیست. آنها برای سهولت در استفاده در مناطقی مانند باغ ها ، انبارها یا پروژه های محوطه سازی در مقیاس کوچک طراحی شده اند. آنها ممکن است بارهای بزرگ یا سنگین را به همان اندازه کارآیی باروهای برق کنترل نکنند ، اما گزینه سازگار با محیط زیست برای کارهای سبک را ارائه می دهند.

3. تحرک و مانور

Barrow Power: Barrows Power اغلب قوی تر است ، برای تحرک بر روی سطوح ناهموار طراحی شده و می تواند در محیط های سخت تر حرکت کند. با داشتن چرخ ها و موتورهای بزرگتر و ناهموار که کشش بهتری را فراهم می کند ، باروهای قدرت می توانند دامنه های شیب دار ، مسیرهای صخره ای و اماکن ساخت و ساز خشن را بدون مشکل زیاد طی کنند.

چرخ دستی برقی: در حالی که چرخ های برقی هنوز هم برای مانور آسان طراحی شده اند ، اما به طور معمول برای زمین های نرم و صاف و کم چالش بهینه بهینه می شوند. آنها در فضاهای جمع و جور ، محدود یا مناطقی که تحرک مهم است اما عملکردی را انجام نمی دهند و همچنین باروهای قدرت در زمین خشن یا ناهموار عمل نمی کنند.

4. برنامه و استفاده

Barrow Power: Barrows Power برای ساخت و سازهای در مقیاس بزرگ ، پروژه های کشاورزی و کارهایی که در آن کنترل مواد شامل بارهای سنگین و سنگین است ، ایده آل است. آنها می توانند مواردی مانند خاک ، شن ، سیمان ، ابزار و آوار را در زمین های خشن حمل کنند و باعث صرفه جویی در وقت و تلاش جسمی شوند.

چرخ الکتریکی : چرخ های برقی برای کارهای کوچکتر از جمله حمل مواد باغ ، وسایل محوطه سازی یا حمل بارهای کوچک در انبارها ، مهد کودک ها و خصوصیات مسکونی به بهترین وجه استفاده می شود. آنها برای نیازهای سبک تر و محدودتر مواد محدودتر در جایی که حداقل قدرت لازم باشد بسیار عالی هستند.

5. هزینه و نگهداری

قدرت بارو: به طور کلی ، با توجه به توان بالاتر ، اندازه بزرگتر و ساخت و سازهای سنگین ، باروهای قدرت گران تر هستند. هزینه های نگهداری نیز می تواند بیشتر باشد ، به خصوص برای مدل های بنزینی ، که نیاز به سوخت و سرویس دوره ای برای موتور دارند.

چرخ دستی برقی: چرخ های برقی به طور معمول هزینه اولیه کمتری دارند و از نظر نگهداری مداوم مقرون به صرفه تر هستند. آنها به تجهیزات بنزین نیاز به نگهداری کمتری دارند زیرا موتور احتراق داخلی ندارند. هزینه های عملیاتی طولانی مدت آنها نیز به دلیل ارزانتر هزینه برق در مقایسه با بنزین کمتر است.

چه تفاوتی بین یک بارو برق و یک چرخ دستی برقی وجود دارد؟

| جنبه | Power Barrow | چرخ الکتریکی |

|---|---|---|

| منبع تغذیه | می توان از بنزین یا برق تغذیه کرد. مدل های بنزین برای استفاده سنگین تر رایج است. | کاملاً با برق تغذیه می شود و آن را سازگار با محیط زیست و ساکت تر می کند. |

| عملکرد و قدرت | قدرت و ظرفیت بالا ؛ قادر به رسیدگی به بارهای بزرگ و سنگین در زمین های خشن. | در مقایسه با مدل های گاز قدرتمندتر است. مناسب تر برای کارهای نور به متوسط و محیط هایی با زمین نرم تر. |

| تحرک و مانور | طراحی شده برای زمین های ناهموار ، از جمله دامنه های شیب دار و زمین های ناهموار ، با چرخ های بادوام. | بهترین برای سطوح صاف و یکنواخت ، ایده آل برای استفاده در فضاهای کوچکتر و محدود. |

| کاربرد | مناسب برای ساخت و ساز ، کشاورزی و کارهای سنگین مانند حمل و نقل شن ، ماسه و سیمان. | در درجه اول برای کارهای سبک مانند باغبانی ، محوطه سازی یا جابجایی مواد کوچک در محیط های شهری یا داخلی استفاده می شود. |

| هزینه و نگهداری | به طور کلی گرانتر ، با هزینه های نگهداری بالاتر به دلیل نگهداری موتور و نیازهای سوخت. | هزینه کمتری و نگهداری آسان تر ، زیرا هیچ هزینه مربوط به سوخت وجود ندارد و سرویس دهی مکرر نیز لازم است. |

چگونه باروهای برق با سایر تجهیزات انتقال مواد مقایسه می شوند؟

Barrows Power فقط یک نوع تجهیزات حمل و نقل مواد است که برای حمل و نقل مواد در سایت های شغلی ، مزارع یا انبارها استفاده می شود. هنگام مقایسه باروهای برق با سایر انواع تجهیزات ، درک مزایا و محدودیت های خاص آنها نسبت به سایر ابزارها مانند چرخ های چرخدار ، لیفتراک و کامیون های زباله مهم است.

1. قدرت بارو در مقابل چرخ های سنتی

قدرت بارو: به عنوان یک وسیله موتوری ، Barrow Power نیاز به کار دستی را هنگام جابجایی مواد از بین می برد. این امکان را به کاربران می دهد تا مقادیر زیادی از مواد را با تلاش جسمی کمی حمل کنند ، و آن را برای مدت طولانی یا کارهای سنگین ایده آل می کنند.

چرخ دستی سنتی: یک چرخ دستی سنتی نیاز به تلاش انسان برای فشار و بلند کردن دارد و باعث می شود کار سخت تر شود. هنوز هم به طور گسترده ای برای کارهای کوچکتر یا در فضاهای محدود که تجهیزات برق نمی توانند مناسب باشند ، مورد استفاده قرار می گیرد. با این حال ، برای کار با مواد سنگین یا فله کندتر و کارآمدتر است.

2. Power Barrow در مقابل لیفتراک ها

قدرت بارو: Barrows Power برای کارهای خاص مانند حمل مواد از طریق زمین های خشن یا فضاهای باریک طراحی شده است. آنها برای حمل و نقل مواد فله در مسافت های کوتاه ، به ویژه در زمین ناهموار بسیار عالی هستند و انعطاف پذیری بیشتری را در مکان های ساختمانی یا مزارع ارائه می دهند.

لیفتراک ها: لیفتراک ها بزرگتر و برای بارهای سنگین تر طراحی شده اند که نیاز به بلند کردن عمودی و مانور دقیق دارند. در حالی که لیفتراک ها می توانند بارهای قابل توجهی سنگین تر از باروهای قدرت داشته باشند ، اما با زمین های چالش برانگیز سازگار نیستند. آنها برای انبارها ، کارخانه ها یا اماکن بزرگ ساختمانی با سطوح جامد و مسطح مناسب تر هستند.

3. Barrow Power در مقابل کامیون های زباله

قدرت بارو: Barrows Power در مانور در فضاهای تنگ و زمین های دشوار برتری دارد. آنها برای پروژه ها و کارهایی که نیاز به دسترسی آسان به مناطق تنگ دارند که کامیون های زباله نمی توانند به آنجا دسترسی پیدا کنند ، مؤثر هستند.

کامیون کمپرسی : کامیون های کمپرسی برای حمل و نقل مقادیر بسیار زیادی از مواد در مسافت های طولانی یا در پروژه های در مقیاس بزرگ مناسب تر هستند. آنها می توانند بارهای گسترده ای داشته باشند اما به دلیل عدم توانایی آنها در حرکت در فضاهای کوچکتر یا سطوح ناهموار به طور کارآمد محدود هستند. Barrows Power شکاف را پر می کند که کامیون های زباله نمی توانند به طور مؤثر کار کنند.

4

Power Barrow : یک بارو برق بسیار جمع و جور تر و آسانتر از یک لودر Skid-Steer است ، به خصوص برای کارهایی که نیازی به بلند کردن سنگین ندارند. بسیار مانور و برای مسافت های کوتاه و زمین های خشن طراحی شده است.

لودر استایر : لودرهای Skid-Steer بزرگتر ، ماشین های قدرتمندتری هستند که برای بلند کردن و حرکت بارهای سنگین در سطوح مختلف استفاده می شوند. در حالی که آنها فوق العاده همه کاره هستند و می توانند کارهای اساسی تری را انجام دهند ، آنها فاقد مانور و فشردگی یک بارو قدرت در فضاهای محدود هستند.

5. Barrow Power در مقابل کامیون های دستی

قدرت بارو: Barrows Power برای تحمل بارهای سنگین تر طراحی شده است و می تواند در مسافت های طولانی تر و زمین های چالش برانگیز تر استفاده شود و تلاش دستی را به میزان قابل توجهی کاهش می دهد.

کامیون های دستی: کامیون های دستی برای حمل بارهای کوچکتر و سنگین تر مفید هستند و به طور معمول برای مواد ظریف تر یا قابل کنترل تر استفاده می شوند. آنها نمی توانند ظرفیت بار مشابهی را با قدرت قدرت تحمل کنند و در هنگام برخورد با حجم بیشتر مواد ، کارآمدتر هستند.

چگونه باروهای برق با سایر تجهیزات انتقال مواد مقایسه می شوند؟

| تجهیزات حمل مواد | Power Barrow | چرخ دستی سنتی | لیفتراک | کامیون | لودر استایر | کامیون دست |

|---|---|---|---|---|---|---|

| منبع تغذیه | موتوری (بنزین یا برقی) | دستی (با نیروی انسانی) | موتوری (بنزین یا برقی) | موتوری (بنزین یا دیزل) | موتوری (بنزین یا دیزل) | دستی (با نیروی انسانی) |

| ظرفیت بار | می تواند بارهای سنگین حمل کند. مناسب برای حمل و نقل مواد فله در مسافت های کوتاه. | ظرفیت بار محدود ؛ تلاش دستی لازم است. | ظرفیت بار بالا ، برای بلند کردن و حمل مواد سنگین استفاده می شود. | ظرفیت بار بسیار بالا ؛ برای حمل و نقل فله از راه دور طراحی شده است. | ظرفیت بار بالا ؛ برای بلند کردن و جابجایی مواد سنگین استفاده می شود. | ظرفیت بار محدود ؛ بهترین برای بارهای کوچکتر و کارهای سبک تر. |

| سازگاری زمین | عالی برای زمین های خشن ، ناهموار یا شیب دار. | محدود بهترین سطوح صاف و صاف. | مناسب برای سطوح مسطح ؛ مبارزات در زمین خشن. | می تواند بر روی سطوح مسطح سفر کند اما نمی تواند زمین های ناهموار را به طور مؤثر اداره کند. | روی سطوح مختلف کار می کند اما ممکن است در مناطق شیب دار یا باریک مبارزه کند. | بهترین برای زمین مسطح ، حتی زمین ؛ برای محیط های خشن مناسب نیست. |

| بهترین استفاده | ایده آل برای ساخت و ساز ، محوطه سازی و پروژه های کشاورزی که نیاز به کار مادی در زمین های دشوار دارند. | بهترین کارهای در مقیاس کوچک مانند باغبانی یا محوطه سازی مسکونی که در آن بارهای کوچک جابجا می شوند. | مناسب برای انبارهای بزرگ ، کارخانه ها و اماکن ساختمانی با کف جامد. | مناسب برای حمل و نقل مواد فله در مقیاس بزرگ ، مانند بقایای ساخت و ساز یا خاک. | بهترین برای بلند کردن و حمل مواد سنگین در سایت های ساختمانی. | عالی برای حمل و نقل اشیاء کوچک و سنگین در مسافت های کوتاه ، مانند جعبه ها. |

| هزینه و نگهداری | با هزینه متوسط تا زیاد ؛ تعمیر و نگهداری مورد نیاز برای موتورها و موتورها. | کم هزینه ، نگهداری کم ؛ استفاده آسان اما از نظر جسمی. | هزینه اولیه بالا ؛ نیاز به تعمیر و نگهداری منظم و سوخت دارد. | هزینه بسیار بالا ؛ تعمیر و نگهداری منظم و سوخت مورد نیاز. | هزینه بالا ؛ تعمیر و نگهداری منظم و سوخت مورد نیاز. | کم هزینه ؛ حداقل نگهداری و بدون هزینه سوخت |

حفظ و مراقبت از یک بارو قدرت

بازرسی و تمیز کردن منظم

انجام بازرسی های منظم

قبل از هر بار استفاده ، بازرسی از قدرت بارو برای هرگونه نشانه سایش و پارگی ضروری است. به دنبال:

قطعات سست یا فرسوده ، از جمله پیچ ، پیچ و لاستیک.

اجزای آسیب دیده مانند کابل ، سیم کشی و قاب.

نشت در سیستم سوخت یا هیدرولیک (برای مدل های بنزین).

پرداختن به هرگونه مسائل احتمالی در حین بازرسی های روزمره می تواند از مشکلات جدی تر در خط جلوگیری کند.

Barrow Power را تمیز کنید

تمیز کردن بارو برق پس از هر بار استفاده ضروری است ، به خصوص اگر در معرض خاک ، گل یا مواد مرطوب قرار داشته باشد. تمیز کردن از ایجاد زباله جلوگیری می کند ، که می تواند بر عملکرد دستگاه تأثیر منفی بگذارد. مناطق کلیدی برای تمیز کردن عبارتند از:

قاب ، چرخ ها و لاستیک ها که باید از بین بروند و شستشو داده شوند تا خاک و خاکستری از بین بروند.

محفظه موتور ، که باید برای جلوگیری از تجمع گرد و غبار یا خاک که می تواند بر موتور تأثیر بگذارد ، تمیز نگه داشته شود.

سیستم اگزوز (برای مدل های بنزین) ، که برای اطمینان از جریان مناسب هوا باید بررسی و تمیز شود.

روغن کاری و مراقبت از روغن

قطعات متحرک را روغن کاری کنید

برای اطمینان از عملکرد صاف ، روغن کاری کردن تمام قطعات متحرک به طور مرتب مهم است. این به کاهش اصطکاک کمک می کند و از سایش و پارگی بر روی اجزای مانند چرخ ، محورها و چرخ دنده ها جلوگیری می کند. همیشه برای حفظ کارایی دستگاه از نوع توصیه شده روان کننده استفاده کنید.

روغن موتور را حفظ کنید

برای مدل های بنزین ، روغن موتور برای نگه داشتن موتور به راحتی بسیار مهم است. با گذشت زمان ، روغن می تواند تخریب شود و بر عملکرد موتور تأثیر بگذارد. به طور مرتب سطح روغن را بررسی کرده و در صورت لزوم ، به دنبال توصیه های سازنده ، آن را تغییر دهید. این عملکرد بهینه موتور را تضمین می کند و عمر Barrow Power را افزایش می دهد.

نگهداری باتری (برای مدل های برقی)

مراقبت مناسب از باتری برای اطمینان از طول عمر و عملکرد باروهای برق ضروری است. نکات کلیدی برای نگهداری باتری شامل موارد زیر است:

باتری را به درستی شارژ کنید : از شارژ بیش از حد یا اجرای باتری برای کاهش کامل خودداری کنید. آن را مرتباً شارژ کنید تا در صورت لزوم آماده استفاده شود.

پایانه های باتری را تمیز کنید: با گذشت زمان ، خوردگی می تواند روی پایانه ها ایجاد شود ، که می تواند کارایی باتری را کاهش دهد. آنها را با یک برس نرم و محلول آب و جوش شیرین تمیز کنید.

باتری را به درستی ذخیره کنید: اگر از Barrow Power برای مدت طولانی استفاده نشود ، باتری را در یک مکان خنک و خشک وصل کنید تا از تخلیه کامل آن جلوگیری شود.

مراقبت از تایر و چرخ

به طور مرتب لاستیک ها را بازرسی کنید

لاستیک ها بخش مهمی از Barrow Power شما هستند ، بنابراین بازرسی از آنها برای هرگونه علائم خسارت ، مانند سوراخ یا ترک ، ضروری است. همچنین ، تراز چرخ و فشار تایر را بررسی کنید تا اطمینان حاصل شود که دستگاه به راحتی حرکت می کند. نگهداری مناسب تایر به جلوگیری از تصادفات و همچنین بهبود مانور کمک می کند.

از تورم تایر مناسب اطمینان حاصل کنید

برای باروهای برق با لاستیک های پنوماتیک ، اطمینان حاصل کنید که آنها به درستی تورم شده اند تا ثبات را فراهم کنند ، از بار پشتیبانی کنند و عملکرد بهینه را در سطوح ناهموار تضمین کنند. لاستیک های زیر تورم می توانند هنگام پیمایش در زمین خشن مشکل ایجاد کنند ، در حالی که لاستیک های بیش از حد تورم می توانند منجر به سایش زودرس شوند.

مراقبت از سیستم موتور و سوخت (برای مدل های بنزین)

نگهداری سیستم سوخت

برای باروهای برق بنزین ، سیستم سوخت برای حفظ عملکرد موتور نیاز به توجه ویژه دارد. همیشه برای جلوگیری از گرفتگی خطوط سوخت و ایجاد مشکلات موتور ، از سوخت تمیز و تازه استفاده کنید. اگر دستگاه برای مدت طولانی استفاده نشود ، سوخت را تخلیه کنید تا از خراب شدن آن و گرفتگی سیستم جلوگیری شود.

نگهداری فیلتر هوا

فیلتر هوا نقش مهمی در اطمینان از دریافت موتور تمیز برای احتراق دارد. به طور مرتب فیلتر هوا را برای هرگونه خاک یا انسداد بررسی کنید و در صورت لزوم آن را تمیز یا جایگزین کنید. یک فیلتر هوای مسدود شده می تواند جریان هوا را به موتور محدود کند و در نتیجه عملکرد ضعیف یا آسیب موتور ایجاد شود.

ذخیره سازی مناسب و زمستان

ذخیره و آماده سازی مناسب برای دوره های عدم فعالیت برای حفظ قدرت شما بسیار مهم است. این که آیا شما برای خرابی فصلی آماده می شوید یا به سادگی دستگاه را در دوره های فعالیت کم ذخیره می کنید ، این شیوه ها اطمینان می دهد که دستگاه در شرایط خوبی باقی می ماند:

Barrow Power را در یک مکان خشک و خنک و دور از نور مستقیم خورشید ، رطوبت و درجه حرارت شدید ذخیره کنید. یک گاراژ پناهگاه یا ریخته شده ایده آل است.

Winterize (برای استفاده فصلی): اگر برای مدت طولانی از Power Barrow استفاده نخواهید کرد ، به ویژه در آب و هوای سرد ، دستورالعمل های سازنده را برای زمستان سازی دستگاه دنبال کنید. این ممکن است شامل تخلیه سوخت ، از بین بردن باتری و پوشاندن دستگاه برای محافظت از آن در برابر گرد و غبار و خاک باشد.

سرویس دهی حرفه ای

در حالی که تعمیر و نگهداری اساسی توسط مالک می تواند انجام شود ، مواقعی وجود دارد که Barrow Power نیاز به توجه حرفه ای دارد. توصیه می شود دستگاه برای بازرسی کامل توسط یک تکنسین حرفه ای سرویس دهی شود ، به خصوص اگر در استفاده منظم بوده یا علائم سایش قابل توجهی را نشان داده است.

خدمات سالانه: بازرسی از ماشین سالانه اطمینان حاصل می کند که همه سیستم ها به درستی کار می کنند و به جلوگیری از مشکلات مهم کمک می کند.

تعمیرات: اگر Barrow Power شروع به نشان دادن علائم نقص مانند صداهای غیرمعمول ، ارتعاشات یا عملکرد ضعیف کند ، به دنبال ترمیم حرفه ای باشید تا از ایجاد آسیب بیشتر جلوگیری شود.

نحوه انتخاب Barrow Power مناسب برای نیازهای خود

انتخاب Barrow Power مناسب به چندین عامل بستگی دارد ، از جمله وظایف خاص مورد استفاده ، نوع زمین و فرکانس استفاده. این که آیا شما در ساخت و ساز ، کشاورزی ، محوطه سازی یا یک صنعت دیگر هستید ، انتخاب قدرت مناسب می تواند باعث افزایش کارایی ، کاهش فشار فیزیکی و بهبود بهره وری شود. در اینجا چه چیزی را باید در هنگام انتخاب خود در نظر بگیرید:

نوع زمین

یکی از مهمترین عوامل در انتخاب یک بارو قدرت ، نوع زمینی است که در آن کار خواهید کرد. در نظر بگیرید که آیا شما نیاز به حرکت دارید:

سطوح مسطح ، آسفالت شده (به عنوان مثال ، انبارها ، محیط های شهری).

زمین های ناهموار و خشن (به عنوان مثال ، سایت های ساختمانی ، مزارع).

مناطق شیب دار (به عنوان مثال ، محوطه سازی یا کار در تپه).

باروهای مختلف قدرت برای محیط های مختلف طراحی شده است ، با ویژگی هایی مانند چرخ های ناهموار ، آهنگ ها یا کشش پیشرفته که به آنها کمک می کند تا سطوح چالش برانگیز را به طور مؤثر کنترل کنند.

ظرفیت و اندازه بار

ظرفیت Barrow Power یکی دیگر از ملاحظات مهم است. به میزان مواد مورد نیاز برای حمل و نقل منظم فکر کنید. ظرفیت بار سنگین تر برای جابجایی مواد فله ای مانند شن ، ماسه و بقایای ساخت و ساز ایده آل است. با این حال ، برای کارهای سبک تر و مکرر ، یک مدل کوچکتر ممکن است کافی باشد.

منبع تغذیه

Barrows Power با منابع مختلف قدرت همراه است:

مدل های بنزین قدرت بیشتری را ارائه می دهند و برای کارهای سنگین مناسب تر هستند.

مدل های برقی ساکت تر ، سازگار با محیط زیست و ایده آل برای کارهای نور به متوسط ، به ویژه در فضاهای شهری یا محصور هستند.

در نظر بگیرید که منبع تغذیه با نیازهای عملیاتی شما و تأثیر محیطی که هدف آن را دارید ، به بهترین وجه تراز می شود.

تحرک و مانور

سهولت مانور یک بارو قدرت یکی دیگر از عوامل مهم است. اگر نیاز به کار در فضاهای تنگ دارید ، از یک مدل مانور جمع و جور و مانور انتخاب کنید که چابکی بیشتری را ارائه می دهد. اگر وظایف شما شامل مسافرت در زمین های خشن برای مسافت های طولانی است ، مدلی را با چرخ های بزرگتر یا آهنگ هایی در نظر بگیرید که می تواند زمین را اداره کند.

بودجه و سرمایه گذاری بلند مدت

در حالی که هزینه همیشه یک عامل است ، سرمایه گذاری بلند مدت را در نظر بگیرید. باروهای با کیفیت بالاتر ممکن است هزینه پیش فرض بالاتری داشته باشد اما از نظر دوام ، کاهش نگهداری و کارآیی پرداخت می کند. مدلی را انتخاب کنید که ضمن ارائه بهترین ارزش از نظر عملکرد و طول عمر ، در بودجه شما متناسب باشد.

چرا Power Barrow را از Wuxi Konstant Power Tech Co. ، Ltd انتخاب کنید

در هنگام انتخاب یک Barrow Power برای عملیات خود ، Wuxi Konstant Power Tech Tech. ، با مسئولیت محدود به عنوان یک تولید کننده قابل اعتماد و قابل اعتماد معرفی می شود. در اینجا به همین دلیل است که شما باید انتخاب یک Barrow Power از این شرکت را در نظر بگیرید:

تعهد به کیفیت

Wuxi Konstant Power Tech به دلیل تمرکز بر تولید باروهای با کیفیت بالا ، با دوام و کارآمد شناخته شده است. ماشین های آنها برای پاسخگویی به خواسته های سخت صنایع مانند ساخت و ساز ، محوطه سازی و کشاورزی طراحی شده اند. با استفاده از فناوری پیشرفته و استانداردهای تولیدی بالا ، می توانید به قابلیت اطمینان و ماندگاری محصولات آنها اعتماد کنید.

گزینه های سفارشی سازی

هر مشاغل نیازهای منحصر به فرد خود را دارد و Wuxi Konstant Power Tech این موضوع را درک می کند. آنها طیف وسیعی از گزینه های سفارشی سازی را برای متناسب کردن Barrow Power به نیازهای خاص شما ارائه می دهند ، و اطمینان می دهند که دستگاهی را دریافت می کنید که کاملاً مطابق با نیازهای عملیاتی شما باشد.

فناوری نوین

این شرکت دارای فناوری پیشرفته در Barrows Power خود است و از عملکرد کارآمد ، نگهداری کم و صرفه جویی در مصرف انرژی برخوردار است. این که آیا شما به دنبال گزینه های برق یا مدل های قوی گاز هستید ، آنها راه حل های مختلفی را برای بهبود بهره وری و کاهش هزینه های عملیاتی ارائه می دهند.

پشتیبانی قوی پس از فروش

انتخاب فناوری قدرت Wuxi Konstant به معنای دسترسی به پشتیبانی استثنایی پس از فروش است. تیم خدمات مشتری آنها به کمک به نصب ، نگهداری ، عیب یابی و ارائه پشتیبانی مداوم برای اطمینان از اینكه قدرت شما در طول چرخه عمر خود به انجام بهینه ادامه می دهد ، کمک می کند.

مقرون به صرفه

با وجود ارائه تجهیزات با کیفیت بالا ، Wuxi Konstant Power Tech راه حل های مقرون به صرفه ارائه می دهد که ارزش عالی برای پول شما را ارائه می دهد. قیمت گذاری و تعهد رقابتی آنها به کارآیی باعث می شود تا قدرت آنها به یک سرمایه گذاری عاقلانه برای مشاغل که به دنبال افزایش قابلیت های حمل و نقل مادی هستند بدون اینکه بیش از بودجه خود باشند ، سرمایه گذاری کند.

روندهای آینده در فناوری Barrow Power

با تکامل صنایع ، فناوری پشت Barrows قدرت نیز همینطور است. با نگاه به آینده ، چندین روند هیجان انگیز در فضای فناوری Barrow Power وجود دارد:

افزایش اتوماسیون

آینده Barrows Power ممکن است شامل ویژگی های خودکار تر مانند قابلیت های خودران یا کنترل از راه دور باشد. این امر نیاز به مداخله دستی ، افزایش کارایی و بهبود ایمنی ، به ویژه در محیط های خطرناک یا پر ترافیک را کاهش می دهد.

طرح های سازگار با محیط زیست

تقاضای فزاینده ای برای راه حل های پایدار و سازگار با محیط زیست در همه صنایع وجود دارد. در پاسخ ، باروهای قدرت آینده احتمالاً شامل مدل های با الکتریکی بیشتری هستند که در مقایسه با مدلهای سنتی بنزین ، انتشار گازهای گلخانه ای کمتری ، کاهش نویز و تأثیر محیطی کمتری را ارائه می دهند.

ویژگی های هوشمند

پیشرفت در فناوری هوشمند می تواند دستگاه های متصل را به Barrows Power منتقل کند. ویژگی هایی مانند نظارت بر زمان واقعی ، نگهداری پیش بینی و ردیابی عملکرد به کاربران کمک می کند تا راندمان دستگاه ، الگوهای استفاده از پیگیری و کاهش خرابی را بهینه کنند.

تحرک و سازگاری پیشرفته

با پیشرفت های مداوم در کار با مواد ، Barrows قدرت آینده احتمالاً شاهد پیشرفت در تحرک خواهد بود. ما می توانیم مدل های قوی تر و همه انگل را ببینیم که برای کار در حتی چالش برانگیزترین مناظر ، بهبود بیشتر بهره وری در محیط هایی مانند مکان های ساختمانی ، مزارع و مناطق معدن طراحی شده است.

عمر باتری بهبود یافته و سرعت شارژ

برای باروهای برق برقی ، پیشرفت در فناوری باتری یک توسعه کلیدی خواهد بود. با بهبود عملکرد باتری ، ما می توانیم انتظار داشته باشیم که باتری طولانی تر و زمان شارژ سریعتر باشد و باعث می شود باروهای برق حتی برای استفاده روزمره کارآمدتر و کارآمدتر شوند.

چرا یک بارو برق یک سرمایه گذاری هوشمندانه برای تجارت شماست

سرمایه گذاری در یک Barrow Power یک تصمیم استراتژیک است که مزایای بی شماری را برای تجارت شما ارائه می دهد ، خواه شما در ساخت و ساز ، کشاورزی ، محوطه سازی یا صنعت دیگری که نیاز به حمل و نقل مکرر دارد ، فعالیت کنید. در اینجا به همین دلیل است که یک Barrow Power یک سرمایه گذاری هوشمند است:

افزایش کارآیی

یک Barrow Power به شما امکان می دهد مواد را خیلی سریعتر از کار دستی یا چرخ های سنتی حمل کنید. با امکان حمل بارهای سنگین تر در مسافت های طولانی تر با حداقل تلاش ، یک بارو برق می تواند به طور قابل توجهی بهره وری را افزایش دهد و به تجارت شما در رسیدن به مهلت های تنگ و کاهش هزینه های نیروی کار کمک کند.

ایمنی و راحتی کارگران بهبود یافته

کار دستی ، به ویژه هنگام بلند کردن مواد سنگین ، می تواند منجر به خستگی کارگران ، صدمات و کاهش بهره وری شود. یک بارو قدرت فشار جسمی را برای کارمندان کاهش می دهد و به آنها امکان می دهد تا با کارآمدتر و ایمن تر کار کنند. این نه تنها روحیه محل کار را بهبود می بخشد بلکه به کاهش خطر تصادفات در محل کار نیز کمک می کند.

تطبیق پذیری and Adaptability

Barrows Power بسیار متنوع است و می تواند برای طیف گسترده ای از کارها ، از حمل مصالح ساختمانی گرفته تا حمل و نقل زباله های خاک یا باغ استفاده شود. چه کار بر روی یک سطح مسطح یا زمین خشن ، باروهای برق برای مقابله با چالش های مختلف ساخته شده اند و آنها را به ابزاری ضروری در صنایع متنوع تبدیل می کند.

صرفه جویی در هزینه بلند مدت

در حالی که هزینه اولیه یک بارو برق ممکن است بالاتر از یک چرخ دستی سنتی باشد ، پس انداز بلند مدت قابل توجه است. کاهش هزینه های نیروی کار ، بهبود کارآیی عملیاتی و کاهش هزینه های مربوط به آسیب ، همه به بازده محکم سرمایه گذاری کمک می کند. علاوه بر این ، با تعمیر و نگهداری مناسب ، یک بارو قدرت می تواند برای سالها به تجارت شما خدمت کند و آن را به یک دارایی مقرون به صرفه تبدیل کند.

مزیت رقابتی

با وارد کردن یک بارو برق در فرآیند کار با مواد خود ، تجارت شما می تواند بهره وری خود را بهبود بخشد ، خرابی را کاهش دهد و کارایی کلی عملیاتی را افزایش دهد. این امر به شما امتیاز رقابتی می دهد که به کار دستی یا تجهیزات منسوخ متکی هستند و به شما امکان می دهد خواسته های مشتری را برآورده کنید و از رقابت جلو بروید.

این که آیا شما به دنبال افزایش کارآیی ، کاهش فشار جسمی یا بهبود ایمنی در سایت شغلی خود هستید ، یک بار قدرت ابزاری اساسی برای مشاغل مدرن است. با انتخاب مدل مناسب برای نیازهای خود ، سرمایه گذاری در تجهیزات با کیفیت بالا مانند شرکت های Wuxi Konstant Power Tech. ، Ltd و به روز ماندن با آخرین روند فناوری ، می توانید اطمینان حاصل کنید که عملیات رسیدگی به مواد شما برای موفقیت طولانی مدت بهینه شده است. $ $ $ $ $ $